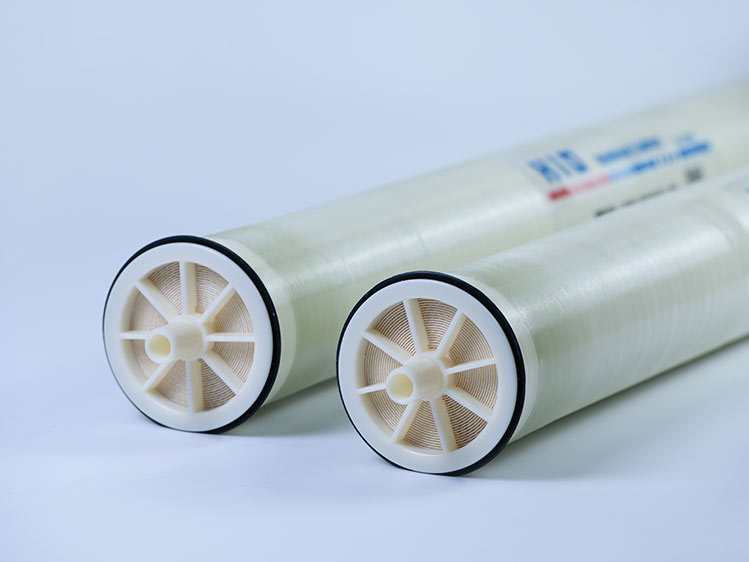

How is reverse osmosis membrane fouling caused? How to solve it?

Membrane fouling is a significant problem which has a negative impact on its performance. It reduces both rejection and flow rate, resulting in higher energy consumption and deterioration of output water quality.

How is reverse osmosis membrane fouling caused?

1. Frequent changes in raw water quality: Due to the increase in impurities such as inorganic matter, organic matter, microorganisms, particulate matter, and colloids in the raw water, membrane fouling may happen more frequently.

2. During running RO system, untimely cleaning and incorrect cleaning methods are also important factors leading to membrane fouling

3. Unproperly add chlorine and other disinfectants during running RO system, coupled with insufficient attention paid by users to microbial prevention, may easily lead to microbial contamination.

4. If the RO membrane element is blocked by foreign objects or the membrane surface is worn (such as sand particles), a detection method should be used to detect the elements in the system and replace the membrane element.

How to reduce membrane fouling?

1. Improve pre-treatment

For each RO plant, people always hope to maximize its effectiveness, with the highest desalination maximum water permeability, and the longest lifespan. Therefore, the quality of water supply is crucial. The raw water entering the RO plant must have good pre-treatment. Reverse osmosis pre-treatment is aimed at: (1) Prevent fouling on the membrane surface, that is, preventing suspended impurities, microorganisms, colloidal substances, etc. from adhering to the membrane surface or blocking the water flow channel of membrane elements. (2) Prevent scaling on the membrane surface. (3) Prevent membrane element from mechanical and chemical damage to ensure good performance and sufficient service life.

2. Clean the membrane element

Despite various pre-treatment measures taken for the raw water, sedimentation and scaling may still occur on the membrane surface after long-term use, leading to clogging of membrane pores and a decrease in pure water production. Therefore, it is necessary to regularly clean the membrane element.

3. Pay attention to the operation during shutdown RO system

When preparing to shut down RO plant, adding chemical reagents can cause the reagents to remain in the membrane and housing, causing membrane fouling and affecting the service life of the membrane. Dosing should be stopped when prepare to shut down RO plant.

Post time: Aug-07-2023