Reverse osmosis (RO) is a membrane separation technology that can remove salt and other dissolved substances from water by applying pressure. RO has been widely used for seawater desalination, brackish water desalination, drinking water purification and wastewater reuse.

The Story Behind the Reverse Osmosis Membrane

Have you ever wondered how a reverse osmosis membrane works? How can it filter out salt and other impurities from water, making it safe and clean to drink? Well, the story behind this amazing invention is quite fascinating, and it involves some curious seagulls.

It all started in the 1950s, when a scientist named Sidney Loeb was working at the University of California, Los Angeles. He was interested in studying the process of osmosis, which is the natural movement of water across a semi-permeable membrane from a region of low solute concentration to a region of high solute concentration. He wanted to find a way to reverse this process, and make water move from a high solute concentration to a low solute concentration, using external pressure. This would allow him to desalinate seawater, and produce fresh water for human consumption.

However, he faced a major challenge: finding a suitable membrane that could withstand the high pressure and resist fouling by salt and other contaminants. He tried various materials, such as cellulose acetate and polyethylene, but none of them worked well enough. He was about to give up, when he noticed something peculiar.

One day, he was walking along the beach, and he saw a flock of seagulls flying over the ocean. He observed that they would dive into the water, catch some fish, and then fly back to the shore. He wondered how they could drink seawater without getting sick or dehydrated. He decided to investigate further, and he discovered that seagulls have a special gland near their eyes, called the salt gland. This gland secretes excess salt from their blood, through their nostrils, in the form of a salty solution. This way, they can maintain their water balance and avoid salt poisoning.

Since then, RO technology has entered a rapid development period and gradually moved towards commercialization. In 1965, the first commercial RO system was built in Coalinga, California, producing 5000 gallons of water per day. In 1967, Cadotte invented the thin-film composite membrane using interfacial polymerization method, which improved the performance and stability of RO membranes. In 1977, FilmTec Corporation started to sell dry-type membrane elements, which had longer storage time and easier transportation.

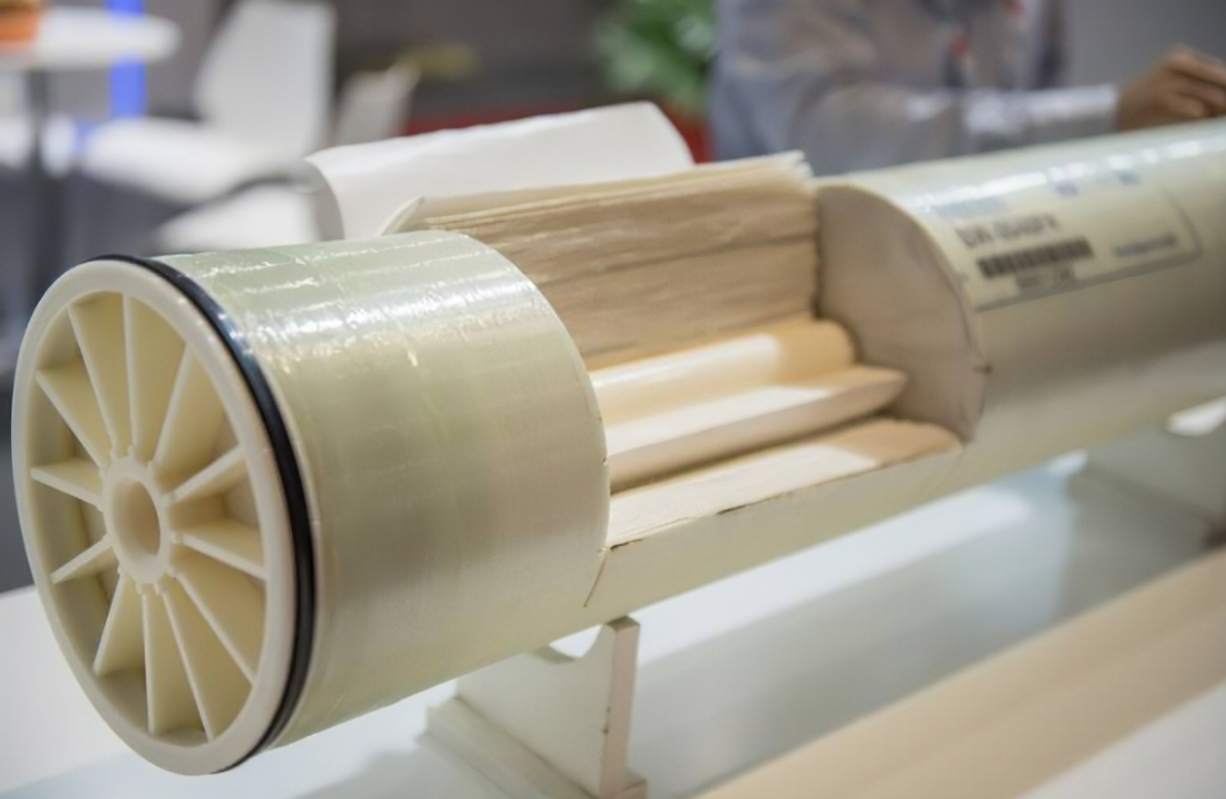

Nowadays, RO membranes are available in various types and sizes, depending on the feed water quality and application requirements. Generally speaking, there are two main types of RO membranes: spiral-wound and hollow-fiber. Spiral-wound membranes are made of flat sheets rolled around a perforated tube, forming a cylindrical element. Hollow-fiber membranes are made of thin tubes with hollow cores, forming a bundle element. Spiral-wound membranes are more commonly used for seawater and brackish water desalination, while hollow-fiber membranes are more suitable for low-pressure applications such as drinking water purification.

To choose the right RO membrane for a specific application, several factors should be considered, such as:

- Salt rejection: The percentage of salt that is removed by the membrane. Higher salt rejection means higher water quality.

- Water flux: The amount of water that passes through the membrane per unit area and time. Higher water flux means higher productivity and lower energy consumption.

- Fouling resistance: The ability of the membrane to resist fouling by organic matter, colloids, microorganisms and scaling minerals. Higher fouling resistance means longer membrane life and lower maintenance cost.

- Operating pressure: The pressure required to drive the water through the membrane. Lower operating pressure means lower energy consumption and equipment cost.

- Operating pH: The range of pH that the membrane can tolerate without damage. Wider operating pH means more flexibility and compatibility with different feed water sources.

Different RO membranes may have different trade-offs between these factors, so it is important to compare their performance data and select the most suitable one according to the specific application conditions.

Post time: Nov-02-2023