Reverse osmosis (RO) ke theknoloji ea karohano ea lera e ka tlosang letsoai le lintho tse ling tse qhibilihisitsoeng metsing ka ho sebelisa khatello. RO e 'nile ea sebelisoa haholo bakeng sa ho ntša letsoai metsing a leoatle, ho hloekisa metsi a letsoai, ho hloekisa metsi a nooang le ho sebelisa metsi a litšila hape.

Pale e ka Morao ho Reverse Osmosis Membrane

Na u kile ua ipotsa hore na lera la reverse osmosis le sebetsa joang? E ka sefa letsoai le litšila tse ling joang metsing, e le hore e be e sireletsehileng le e hloekileng ho nooa? Ha e le hantle, pale ea tšibollo ena e hlollang e khahla haholo, 'me e ama matata a leoatle a batlang ho tseba.

Tsohle li qalile ka bo-1950, ha rasaense ea bitsoang Sidney Loeb a ne a sebetsa Univesithing ea California, Los Angeles. O ne a thahasella ho ithuta ka tšebetso ea osmosis, e leng mokhoa oa tlhaho oa ho tsamaea ha metsi ho pholletsa le lera le khonang ho phunyeletsa ho tloha sebakeng se nang le solute e tlaase ho ea sebakeng sa solute e ngata. O ne a batla ho fumana mokhoa oa ho khutlisa ts'ebetso ena, le ho etsa hore metsi a tsamaee ho tloha sebakeng se phahameng sa solute ho ea sebakeng se tlaase sa solute, a sebelisa khatello ea ka ntle. Sena se ne se tla mo lumella ho ntša letsoai metsing a leoatle, le ho hlahisa metsi a hloekileng a sebelisoang ke batho.

Leha ho le joalo, o ile a tobana le phephetso e khōlō: ho fumana lesela le loketseng le neng le ka mamella khatello e phahameng le ho hanela ho silafatsoa ke letsoai le lintho tse ling tse silafatsang. O ile a leka lisebelisoa tse sa tšoaneng, tse kang cellulose acetate le polyethylene, empa ha ho le e 'ngoe ea tsona e sebetsang hantle ka ho lekaneng. O ne a le mothating oa ho tela, ha a hlokomela ntho e 'ngoe e makatsang.

Ka letsatsi le leng, o ne a ntse a tsamaea lebōpong la leoatle, ’me a bona mohlape oa matata a leoatle o fofa holim’a leoatle. O ile a hlokomela hore li ne li tla itahlela ka metsing, li tšoase litlhapi, ebe li fofa li khutlela lebōpong. O ne a ipotsa hore na ba ka noa joang metsi a leoatle ntle le ho kula kapa ho felloa ke metsi. O ile a etsa qeto ea ho batlisisa ka ho eketsehileng, ’me a fumana hore matata a leoatle a na le tšoelesa e khethehileng haufi le mahlo a ’ona, e bitsoang tšoelesa ea letsoai. Tšoelesa ena e ntša letsoai le feteletseng maling a tsona, ka linko tsa tsona, ka mokhoa oa motsoako o letsoai. Ka tsela ena, ba ka boloka botsitso ba bona ba metsi mme ba qoba chefo ea letsoai.

Ho tloha ka nako eo, theknoloji ea RO e kene nakong ea tsoelo-pele e potlakileng 'me butle-butle e ile ea fallela khoebong. Ka 1965, tsamaiso ea pele ea khoebo ea RO e hahiloe Coalinga, California, e hlahisa lilithara tse 5000 tsa metsi ka letsatsi. Ka 1967, Cadotte o ile a qapa lesela le entsoeng ka filimi e tšesaane e sebelisang mokhoa oa interfacial polymerization, o ileng oa ntlafatsa ts'ebetso le botsitso ba li-membrane tsa RO. Ka 1977, FilmTec Corporation e ile ea qala ho rekisa li-membrane tsa mofuta o omileng, tse neng li e-na le nako e telele ea polokelo le lipalangoang tse bonolo.

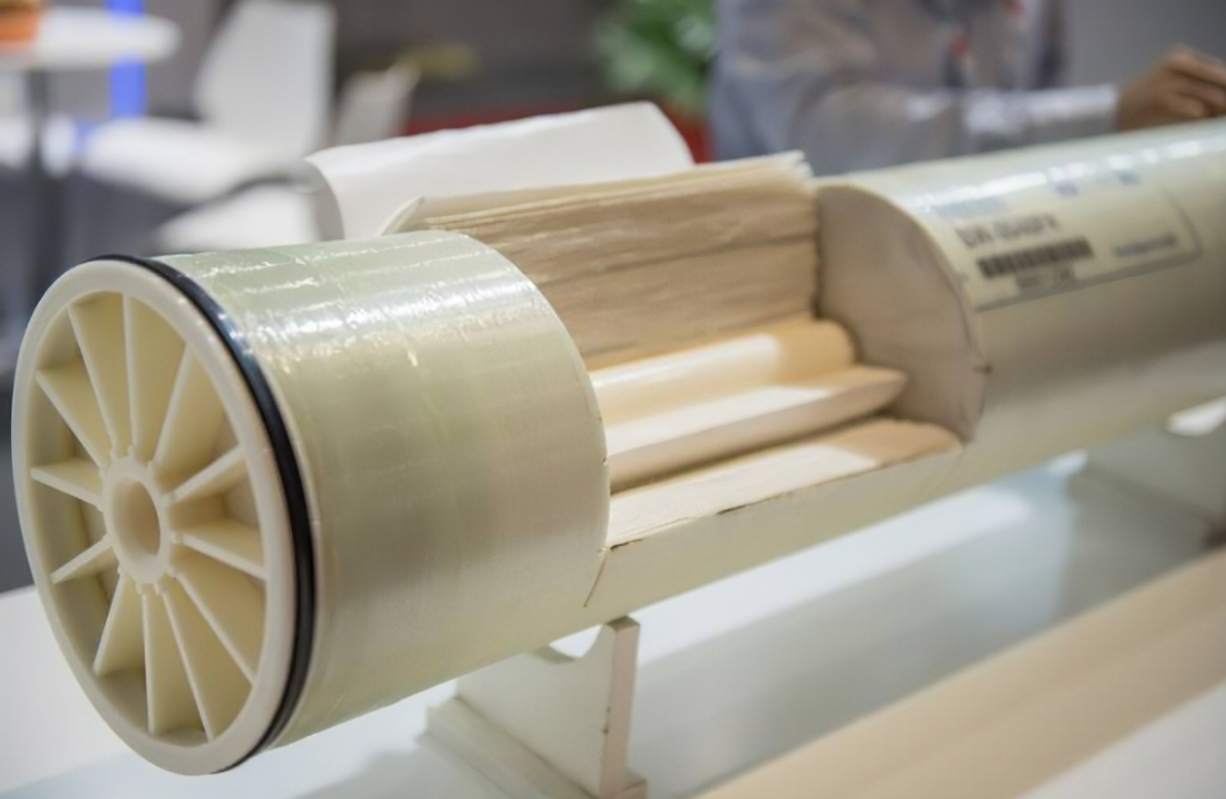

Matsatsing ana, li-membrane tsa RO li fumaneha ka mefuta le boholo bo fapaneng, ho latela boleng ba metsi a phepelo le litlhoko tsa ts'ebeliso. Ka kakaretso, ho na le mefuta e 'meli ea mantlha ea li-membrane tsa RO: spiral-wound le hollow-fiber. Li-membrane tsa maqeba a spiral li entsoe ka maqephe a bataletseng a pota-potiloeng ho pota-potile tube e nang le liphahlo, a etsa karolo ea cylindrical. Li-membrane tsa sekoti-fiber li entsoe ka li-tubes tse tšesaane tse nang le li-cores tse sekoti, tse etsang karolo ea bongata. Li-membrane tsa maqeba a Spiral li sebelisoa haholo bakeng sa ho ntša metsi a leoatle le ho ntša letsoai metsing a letsoai, ha li-membrane tsa sekoti-fiber li loketse haholo lits'ebetsong tse nang le khatello e tlase joalo ka tlhoekiso ea metsi a nooang.

Ho khetha membrane e nepahetseng ea RO bakeng sa ts'ebeliso e itseng, lintlha tse 'maloa li lokela ho nahanoa, tse kang:

- Ho hana letsoai: Peresente ea letsoai le ntšoang ke lera. Ho hana letsoai le phahameng ho bolela boleng bo phahameng ba metsi.

- Phallo ea metsi: Palo ea metsi a fetang ka har'a lera sebakeng le nako ea yuniti. Phallo e phahameng ea metsi e bolela tlhahiso e phahameng le tšebeliso e tlase ea matla.

- Fouling resistance: Bokhoni ba lera ho hanela ho silafatsoa ke lintho tse phelang, li-colloid, likokoana-hloko le liminerale tse ntseng li eketseha. Khanyetso e phahameng ea fouling e bolela bophelo bo bolelele ba membrane le litšenyehelo tse tlase tsa tlhokomelo.

- Khatello ea ho sebetsa: Khatello e hlokahalang ho khanna metsi ka lera. Khatello e tlase ea ts'ebetso e bolela tšebeliso e tlase ea matla le litšenyehelo tsa lisebelisoa.

- pH e sebetsang: Mefuta e fapaneng ea pH eo lera le ka e mamellang ntle le tšenyo. PH e pharaletseng ea ts'ebetso e bolela ho fetoha le maemo ho feta le ho lumellana le mehloli e fapaneng ea metsi a phepelo.

Li-membrane tse fapaneng tsa RO li ka 'na tsa e-ba le mekhoa e fapaneng ea khoebo pakeng tsa lintlha tsena, kahoo ke habohlokoa ho bapisa lintlha tsa bona tsa ts'ebetso le ho khetha e loketseng ka ho fetisisa ho latela maemo a khethehileng a kopo.

Nako ea poso: Nov-02-2023