1600gpd High Flux Reverse Osmosis RO Membrane TFC-3413-1600G

HIDTM Industrial Reverse Osmosis Membrane ranks the best brands in China among RO membrane industry. It has won the trust of thousands of families for feeding the reliable purified water over 10 years. Each membrane is made of HID developed & pre-examined sheet and goes through stringent making processes as well as in-house quality inspection & testing before delivery. HID Membrane has been certified by SGS & China Jiangsu Sanitation Bureau wrt drinking water membrane elements.

HIDTM Commercial JUMBO RO Membranes:

HIDTM Commercial JUMBO RO Membrane ranks the best brands in China among RO membrane industry. It has

met with the latest industry demand of much higher pure water flux with commercial RO system. Each membrane

is made of HID developed & pre-examined sheet and goes through stringent making processes as well as in-house

quality inspection & testing before delivery.

HID Membrane has been certified by SGS & China Jiangsu Sanitation Bureau with drinking water membrane elements.

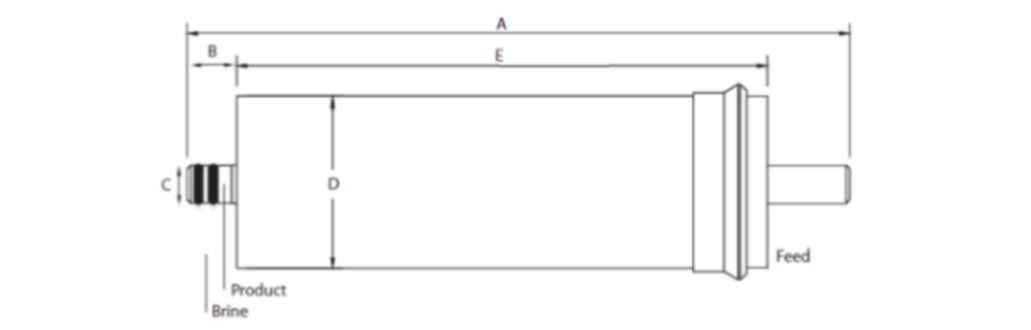

RO Membranes Dimensions:

| Model No. | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) |

| TFC-3413-1600 | 330 | 19 | 16.8 | 92 | 300 |

RO Membrane Performance Specifications:

| Model No. | Min. Salt Rejection (%) |

Stabilized Salt Rejection (%) |

Permeate Flow Rate GPD(ml/min) | Test Temp. | Test Pressure (psi) |

Test water TDS (ppm) |

| TFC-3413-1600 | 94 | 96 | 1600(4206) | 25℃ | 100 | 500 |

1. Permeate flow rate and salt rejection is based on testing conditions: 25⁰C, pH 7.5, 50% recovery.

2. Stabilized salt rejection is generally achieved within 24-48 hours of continuous use, depending upon feedwater

characteristics and operating conditions. Active area guaranteed +/- 3%.

3. Flow rates for individual elements may vary but will be no more than 15% below the value shown.

RO Membranes Operating Limits:

| Model No. | Maximum Operating Temperature |

Maximum Operating Pressure |

Feed Water PH Range, continuous operation |

Maximum Feed Water Turbidity |

Maximum Feed Water SDI |

Chlorine Tolerance |

| TFC-3413-1600 | 45℃ | 200psi | 4-11 | 1NTU | 5 | <0.1ppm |

RO Membranes Operation Guidelines:

It is CRITICAL to avoid any abrupt pressure or cross-flow variations on the RO membrane elements during start-up, shutdown, cleaning or other sequences to prevent possible membrane damage. During startup, a gradual change from a standstill to operating state is recommended as follows:

• Feed pressure should be increased gradually over a 30-90 second time frame.

• Cross-flow velocity at set operating point should be achieved gradually over 15-30 seconds.

• Permeate obtained from the first hour of operation should be discarded.

RO Membranes Important Information:

Keep RO membrane elements moist at all times after initial wetting.

If operating limits and guidelines given in this specification are not strictly followed, the limited warranty with the supplier will be null and void.

To prevent biological growth during prolonged system shutdowns, it is recommended that RO

membrane elements be immersed in a storage solution.

The customer is fully responsible for the effects of incompatible chemicals and lubricants on elements.

Maximum pressure drop across an entire pressure vessel (housing) is 50 psi (3.4 bar).

Avoid static permeate-side backpressure at all times.

HID RO Membranes are widely used in ultra-pure water, process pure water, cooling tower water, boiler water supply, pure water, throughout the electronics industry, optoelectronic industry, machinery manufacturing, fine chemical industry, medical pharmaceutical, food, and beverage industry, surface coating, and many other industries.